- HOME

- Technology & Trends

- How visual collaboration is revolutionizing the way manufacturing teams work

How visual collaboration is revolutionizing the way manufacturing teams work

- Last Updated : December 29, 2025

- 75 Views

- 10 Min Read

In manufacturing, work rarely moves linearly. Teams jump between planning, production, quality checks, documentation updates, and countless decisions that need to happen fast and happen right. Yet most collaboration tools available today were designed for generic office work, not the complexities of a production floor. They handle documents and tasks reasonably well, but they fail to provide the real-time visual clarity needed to manage interconnected manufacturing processes.

As a result, a single production cycle often depends on scattered emails, spreadsheets, chats, drives, screenshots, and lengthy SOPs. A visual collaboration tool fundamentally changes the experience, bringing clarity and structure into environments where precision and speed are critical.

What does visual collaboration really mean in manufacturing?

When people hear “visual collaboration,” they usually think of brainstorming sessions or colorful sticky notes. But in manufacturing, the value of visual collaboration is far more operational.

It means helping teams see processes the way they actually work rather than the way they’re described in text.

It allows planning, workflows, checklists, equipment layouts, quality steps, and documentation to live in the same space. This type of shared visibility ensures that everyone has access to accurate, real-time information in a format that is accessible even to non-technical team members.

Visual collaboration becomes the foundation for faster decision-making, clearer communication, and reduced production waste.

Why do manufacturing teams need a unified visual space like Vani?

Manufacturing is the heart of every product-driven company. From planning and design to production and quality assurance, teams juggle a massive amount of interconnected work under a tight timeline. Unfortunately, this work is frequently split across separate software tools that don’t talk to each other, making communication slow and inefficient.

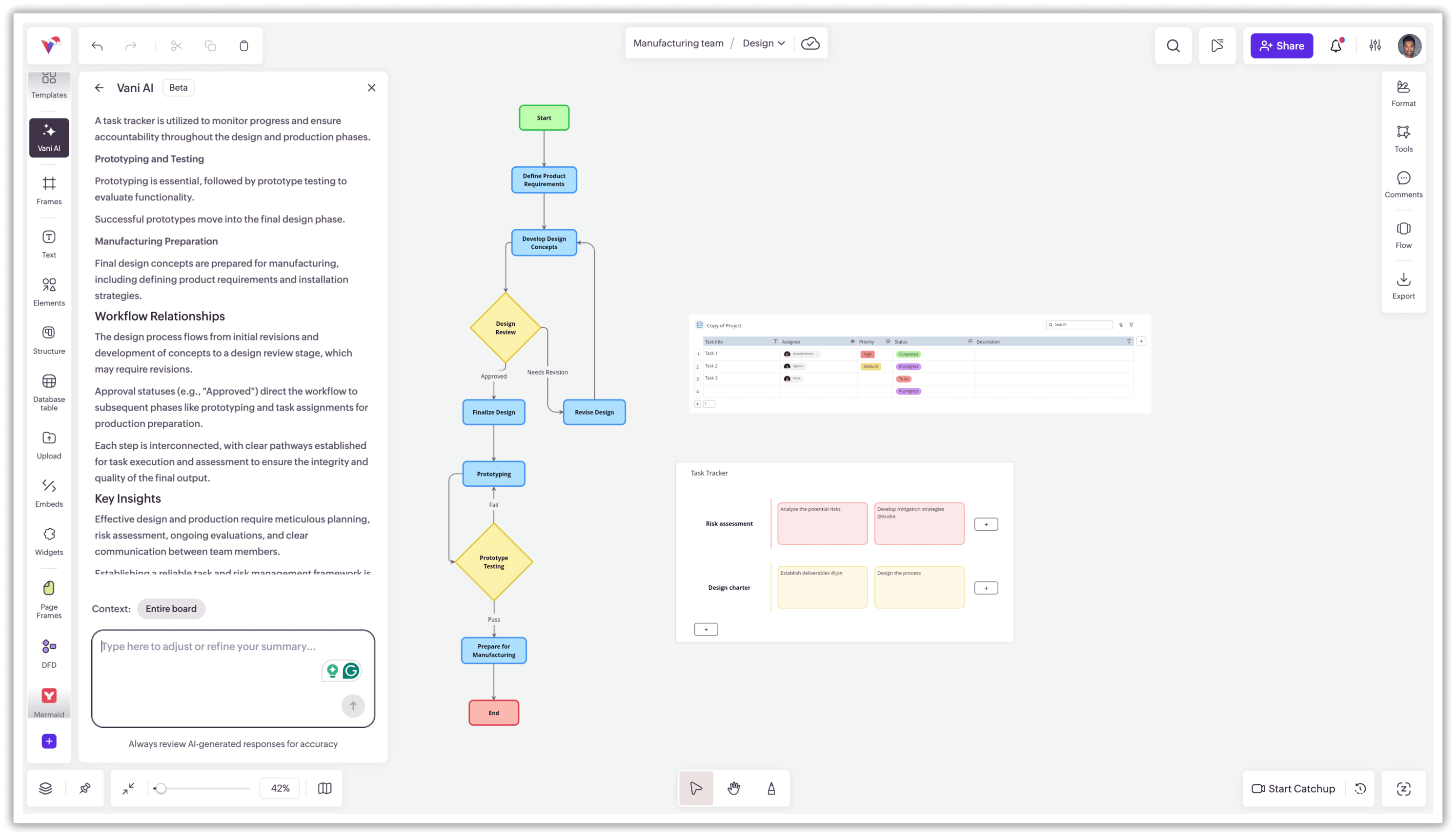

A unified visual workspace like Vani eliminates that fragmentation. It brings planning, execution, documentation, and communication into one environment, allowing teams to collaborate more naturally. When every flow, checklist, annotation, SOP, and task lives on a single canvas, manufacturers reduce miscommunication, prevent errors, and accelerate their ability to adapt to changes.

Below are real, everyday use cases manufacturing teams can instantly relate to.

Brainstorm and plan more effectively

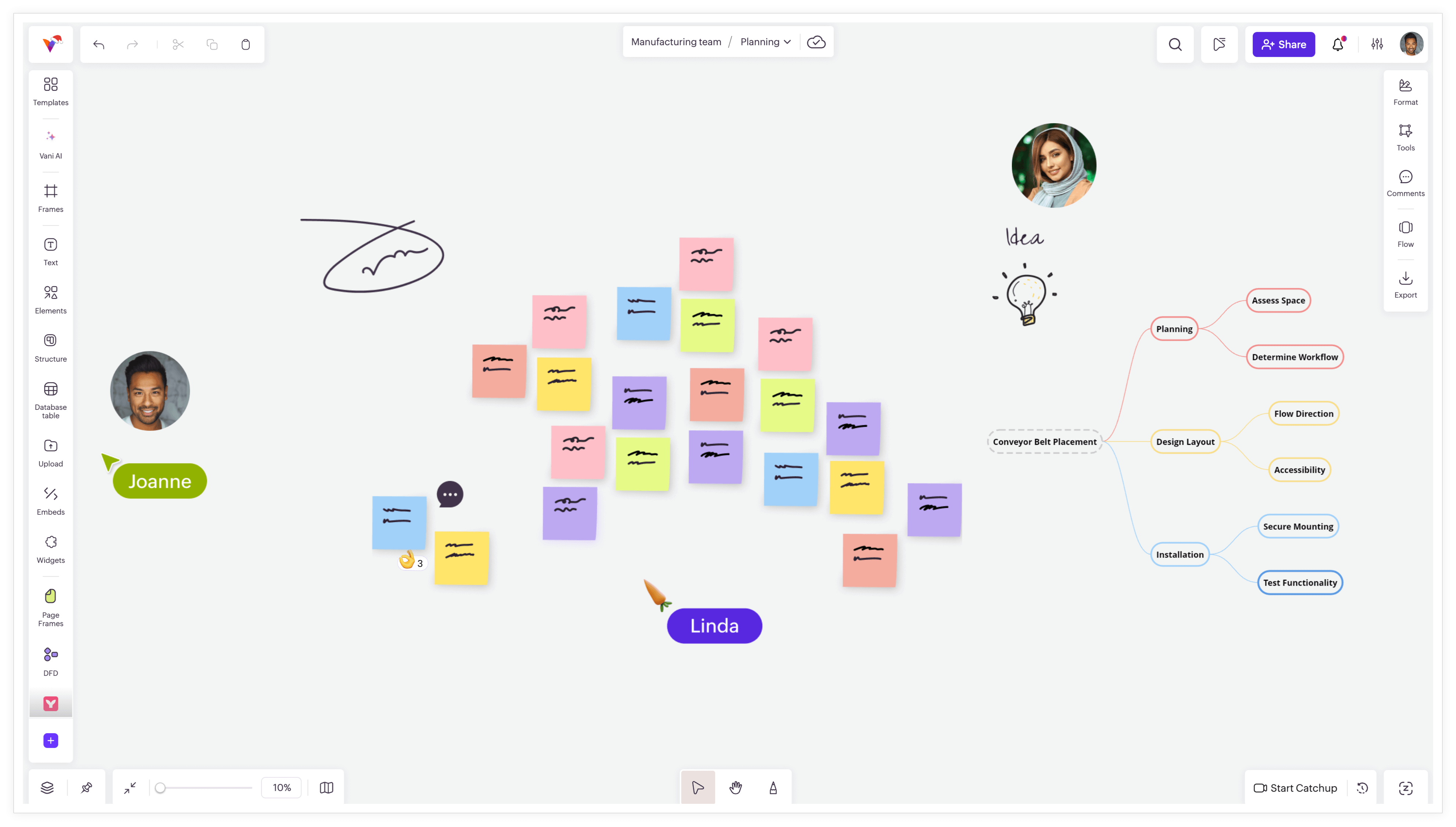

Planning in manufacturing often requires multiple rounds of brainstorming to address challenges like capacity issues, line balancing, new product introduction, or equipment improvements. Vani provides an infinite visual canvas where teams can explore ideas in a structured yet flexible way. Instead of static documents, they can create mind maps, sketch concepts, map potential improvements, or analyze bottlenecks together. Because the canvas updates in real time, both on-site and remote team members can contribute simultaneously.

Vani AI also supports early-stage planning by generating ideas that help teams begin complex discussions more confidently. This creates a more inclusive and collaborative planning atmosphere that speeds up alignment.

Map complex processes in real time

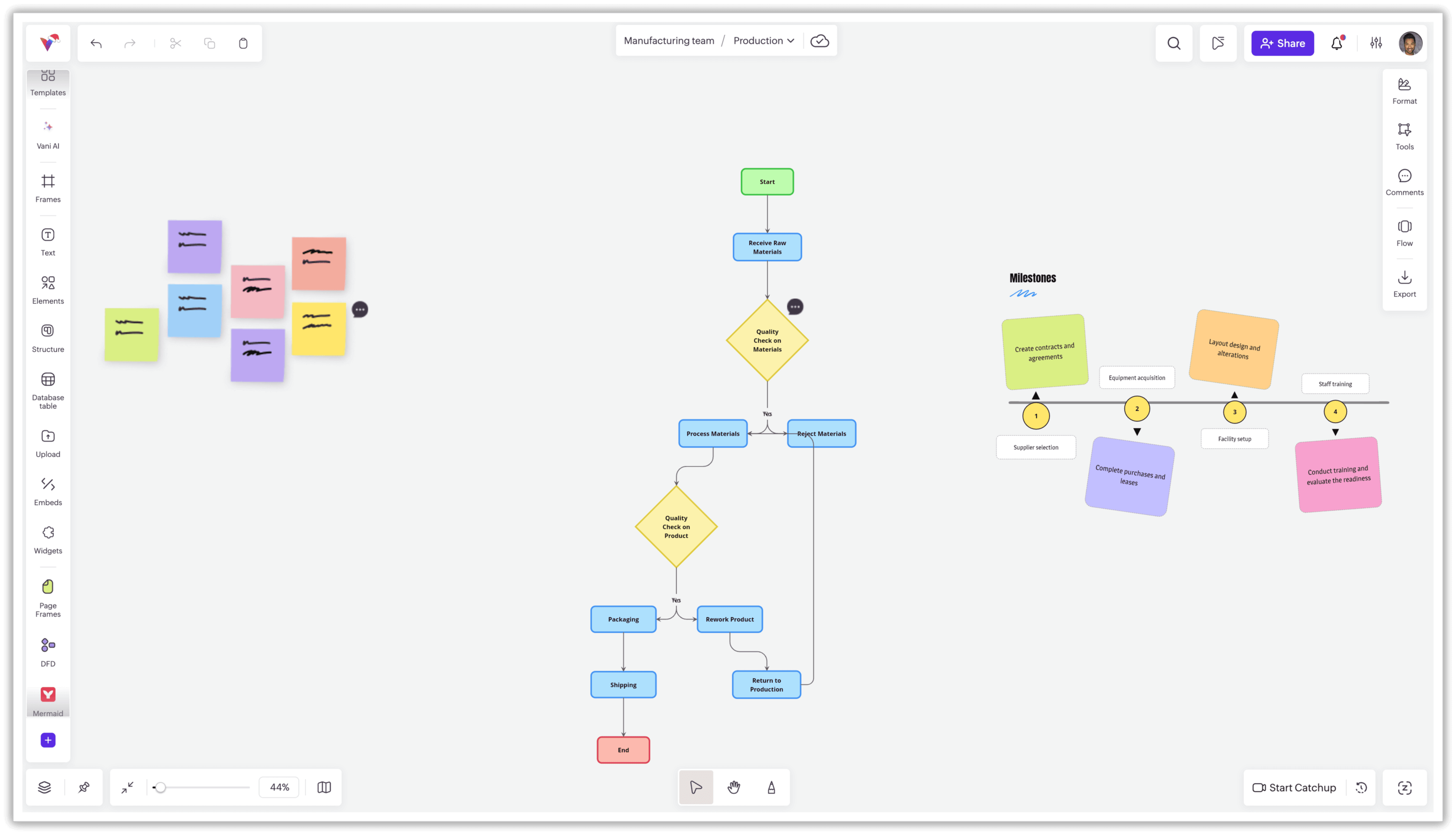

Whether it’s molding, casting, packaging, batch production, continuous processing, machine setup, or quality checkpoints, Vani lets you map out processes exactly the way your team understands them—visually.

Teams can add comments on specific steps, pin issues where they occur, record voice notes, jump on quick video calls directly from the canvas, or review recorded calls later. Manufacturers can finally maintain living, breathing process maps—not outdated static documents.

Manage projects and tasks in one place

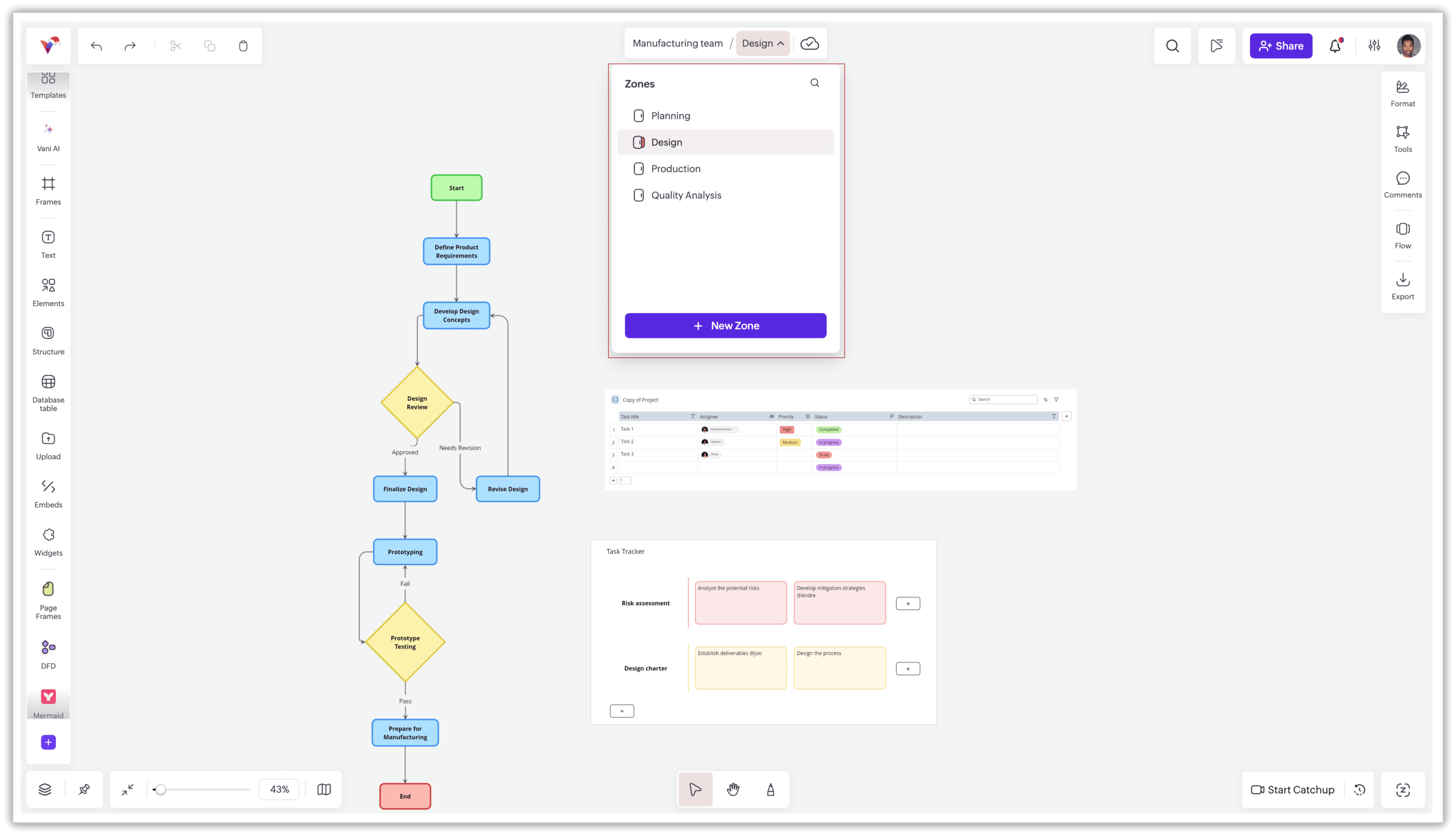

Manufacturing projects like plant upgrades, production scaling, changeovers, or maintenance cycles often involve multiple systems, approvals, and dependencies. Vani brings these elements together so operations managers, production heads, and supervisors can manage tasks without switching platforms.

The Space and Zone structure allows teams to separate different projects while still viewing the overall workflow in a cohesive visual format.

Using kanban-style task management, teams can track what stage a product or component is in, identify delays, and assign responsibilities instantly. The advantage of having tasks embedded within a visual canvas is that decisions happen with full context, reducing miscommunication and enabling faster follow-through.

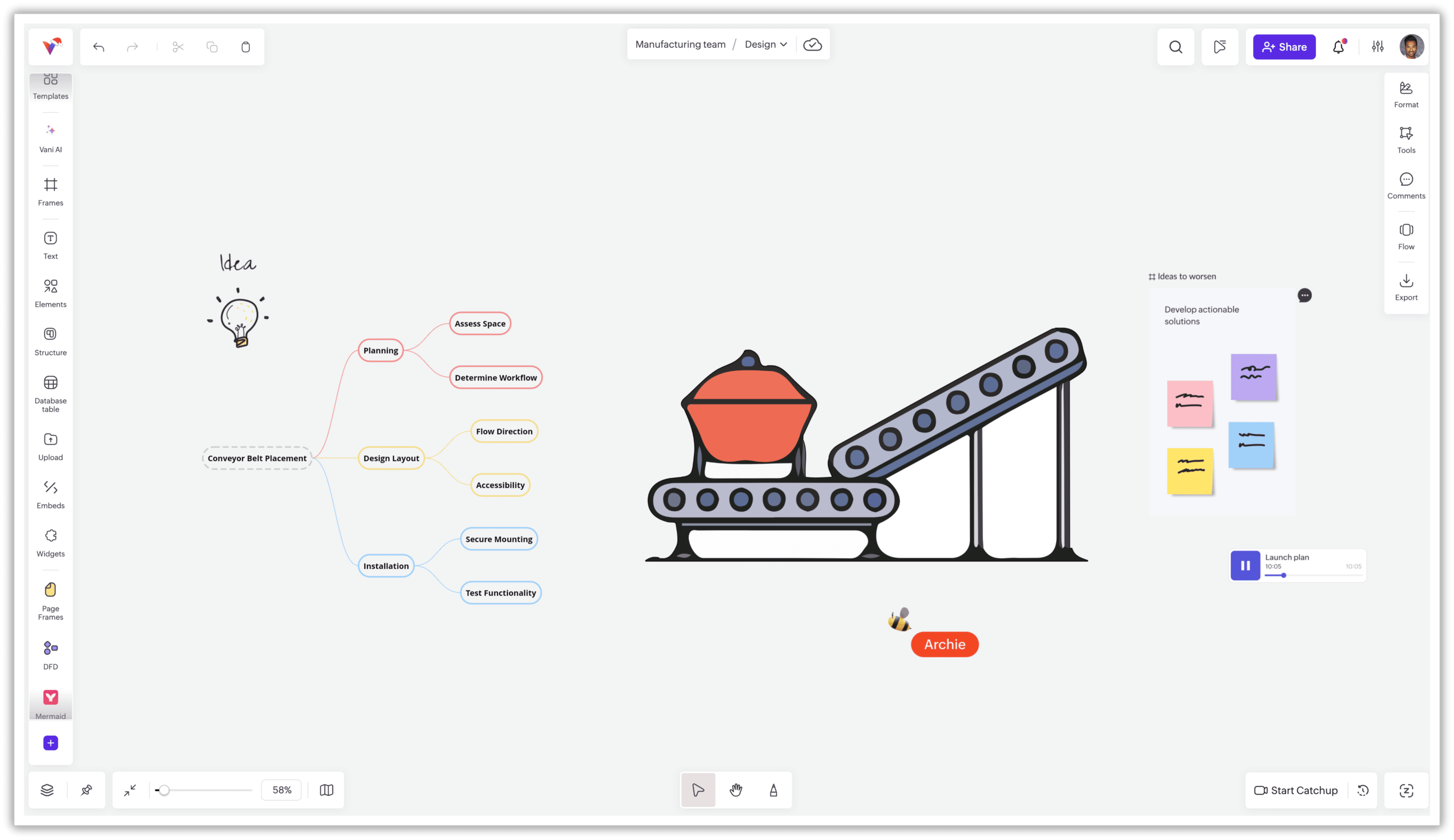

Design your layouts before moving to CAD

Manufacturing design work requires creating floor layouts, machinery placements, workstation blueprints, and assembly line flows. These usually begin with rough sketches or early drafts before going into CAD systems. Vani serves as an ideal space for this pre-CAD phase.

Teams can visually outline equipment positions, process sequences, and movement paths on the canvas. Mechanical engineers, production supervisors, and planners can collaborate on high-level visual designs and resolve potential conflicts early.

This reduces costly rework when designs eventually move to CAD tools. With templates and manufacturing-specific design kits, Vani supports teams who need to visualize complex machinery or workflow interactions before committing to the final detailed build.

Generate reports and present instantly

Reporting is a significant part of manufacturing work, from compliance reports and daily shift summaries to audit documentation and production analysis. Traditionally, reports require manually gathering information from multiple tools, visualizing it, formatting it, and then presenting it. Vani simplifies this by enabling teams to summarize entire canvases using Vani AI, turning complex visual information into readable, structured reports within seconds.

Presentations can be delivered directly from the canvas using Vani Flow or exported into platforms like Zoho Show for further customization. This drastically reduces reporting time while maintaining accuracy and clarity.

Strengthening cross-functional collaboration across the organization

A product’s journey does not end at production. It transitions between departments—moving through quality checks, operations teams, planning managers, marketing discussions, sales timelines, and customer support processes. Misalignment between these functions can create delays or misinterpretations.

Vani offers a shared visual space where all teams stay informed about the same production updates, schedules, changes, and documentation. Because every department sees the same real-time version of the process, they collaborate more efficiently, eliminate redundancy, and respond faster to unexpected challenges. This cross-functional visibility is especially valuable in high-mix, fast-paced manufacturing environments where delays ripple across the whole organization.

Transforming training and onboarding with visual guidance

Manufacturing onboarding can be overwhelming, especially for new hires who need to learn processes, equipment usage, safety protocols, and organizational structures. Visual onboarding through Vani removes the guesswork. New employees can explore visually mapped workflows, machinery instructions, SOPs, procurement processes, and team responsibilities all on a single canvas. Instead of navigating multiple training documents, they receive a visually cohesive guide that reflects the real system they’ll work in, creating a more intuitive work experience rather than heavy text documents. This accelerates learning curves and ensures consistent training across shifts and departments.

Supporting continuous improvement and quality management

Continuous improvement lies at the heart of every successful manufacturing culture. Vani supports this by allowing teams to track issues where they occur, annotate root causes, document corrective actions, and maintain historical records of improvements.

Quality teams can visually pin deviations directly on process maps and collaborate with production teams to resolve them quickly. By visually documenting every issue from minor setbacks to major defects, organizations build a reliable record that prevents repeated failures, minimizes downtime, and drives sustainable process improvement.

Enter the new era of manufacturing collaboration

Manufacturing teams operate in some of the most demanding environments, where precision, speed, and clear communication directly affect operational success. Traditional collaboration tools often slow them down rather than support them. Visual collaboration introduces a new way of working—one that aligns teams, speeds up decisions, reduces errors, and keeps processes transparent. Vani brings these benefits together by offering a single infinite canvas where manufacturing teams can plan, document, communicate, and improve with confidence. As manufacturing processes grow more complex, adopting a unified visual workspace is no longer a luxury; it's a strategic shift that allows teams to operate with greater clarity and efficiency.